[vimeo http://vimeo.com/77617249]

Jannis Hülsen's Xylinum Stool

Xylinum is a bacteria that consumes sugar and produces an artificial cellulose material, a random three dimensional fibre nano structure. It can grow around any given form. The properties of this material can be changed by changing the genetic code of the organisms. Jannis Hülsen, in collaboration with Jenpolymers, developed a technique to create a skin around a wooden fram, forming a coating and the seating surface.

Here is a very informative video from Jannis explaining the process.

Xylinum from Jannis Hülsen on Vimeo.

X-Federation Chair by Victor Vetterlein - Imbedding carbon fiber into wooden veneer

The 'X-Federation' chair by New York-Based Designer Victor Vetterlein uses a combination of laminated wood, combined with carbon-fiber to achieve a very slim and minimal look without compromising the weight-bearing function a chair requires. The technique first started in boat building and was further developed in the skateboard industry, which is where I first encountered this technique but was somewhat skeptical. (I have 2 Sector 9 Cloud 9 skateboards, very thin wooden veneer decks. Very maneuverable and a joy to ride. Sector 9 doesn't seem to make them this way any more. They use fiber glass now. Here's a that proves the strength of this kind of construction.)

The design includes a thin steel frame under the seat where the legs are mechanically fastened. The armrest is optional and fastens to the back and sides of the chair.

The X-Federation Elite Class chair comes with a solid brass armrest and leg sleeves. Must say, the contrast in materials is very interesting.

[via http://www.fastcodesign.com/1670183/using-the-secrets-of-skateboard-tech-to-build-a-better-chair and http://cubeme.com/blog/2012/06/27/x-federation-chair-by-victor-vetterlein/]

What in the world is Liquid Wood?

The Milan Design Week has started and among the many pieces of furniture that has already caught my attention, the material used by Calligaris caught my attention: Liquid Wood.

It's really a material and process combination: an air-molding technique that involves Polypropylene and glass fiber being injected at the same time. Calligaris describes it as a composite biomaterial of polymer and wood, recyclable and produced with raw materials that are easily available and renewable. The liquid wood is molded like a normal thermoplastic polymer allowing for great versatility and high performance in terms of durability, resistance and flexibility. It is mainly composed of lignin and cellulose, which together with hemicellulose make up the stem cells of plants.

Found via [Gizmag]

Christofer Ödmark's "The Desk"

Swapnil sent me a link to Christofer Ödmark's desk. Like mine, it features a large workspace but he goes further to use solid oak, along with steel for his legs.

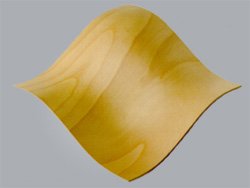

3D Veneer

Following up on the exploration three dimensional weaving with wood, the more conventional method of creating three dimensional wooden objects using plywood pioneered by the Eames and Saarinen was further improved on with 3D Veneer. One company that manufactures this material is Reholz.

The image on the left is what happens when the shape is molded with conventional plywood. The image on the right is the same shape with 3D Veneer.

Referenced on Reholz's website is Ron Arad's Three Skin Chair, which is an excellent example of the application of 3D Veneer.