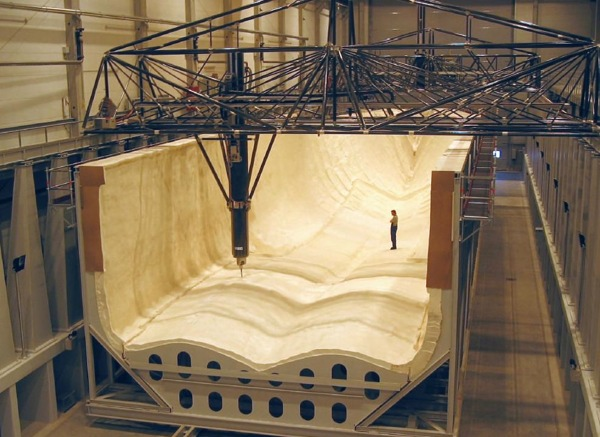

Xylinum is a bacteria that consumes sugar and produces an artificial cellulose material, a random three dimensional fibre nano structure. It can grow around any given form. The properties of this material can be changed by changing the genetic code of the organisms. Jannis Hülsen, in collaboration with Jenpolymers, developed a technique to create a skin around a wooden fram, forming a coating and the seating surface.

Here is a very informative video from Jannis explaining the process.

Xylinum from Jannis Hülsen on Vimeo.